Pioneer in Thermal Transfer Labels and Ribbon - Argon Technology Corporation

Posted by Admin on 14th Mar 2021

As a pioneer in network boot solutions, Argon Technology is specialized in network booting tools that streamline customer administration, increase customer safety and minimize overall ownership costs. Argon Technology provides a wide range of products supporting hundreds of common PXE, TCP/IP, NetWare and RPL network interface (NIC) cards.

Argon's technology is licensed to major technology providers and Argon developer firmware is installed at millions of workstations worldwide. Products from Argon Technology allow you to save time and money through the integrity of the boot process for customers, day after day.

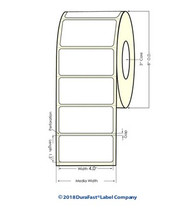

Argon Technology Corporation provides a wide range of thermal transfer labels for the barcode and thermal label printing for both your desktop and industrial applications.

They have a smooth, white surface for crisp, bar-coded labels and excellent print quality on thermal transfer labels. Both adhesive labels and adhesive-free tags are possible. The rectangular and square forms are given in sizes.

There are a number of different label categories, including:

- Matte labelling is suitable for a variety of labels and bar codes for general purposes.

- Matte labels in polypropylene include shipping labels, pupil-base labels and wood label with smudge-proof printing, with a maximum of one-year outdoor usability.

- Polyester labels are well suited for weather proof applications of thermal transmission for outdoor applications, such as paddling plants, plant nurseries, etc.

Thermal transmission bar code printers use heat and coated ribbon on thermal transmission labels to print barcodes, graphics and texts. A wide range of thermal transfer labels was developed by Argon Technology specifically for use in thermal transfer printers.

With thermal transfer printers, thermal transfer labels can be produced from various materials. Installing the thermal transfer ribbons are used, which are thin synthetic films covered with wax, resin or a wax-resin mixture, rather than using liquid ink or dry toner. A heated printer heats the belt to generate the image. The mark faces the covered side of the ribbon. The wax or resin coating is melt by thermal heat on the thermal transfer label which produces a printed label.

The use of a ribbon is not necessary for direct thermal printers, and direct thermal labels must be heat activated. Certain printers with thermal labels may be used to print thermal or thermal transfer labels direct. Though you have to use a thermal transfer ribbon, improved longevity and lifespan are the main advantages of using thermal label printing over direct thermal printing.

Argon Technology Corporation also provides a wide range of thermal transfer ribbon. Thermal transmission label printers use various types of thermal transmission ribbons that can be covered with wax or polyester film or pure resin. Different types of resins used in thermal transmission ribbons are designed to print different applications, such as a harsh environment.

If combined with a coated or smooth label of Paper, the wax bands may produce fine quality images. In such forms of resins, however, interaction with water does not exist. Ribbons made of purified resins, including vinyl or polyester, are printed on the plastic labels and the resin can dissolve slightly on the plastic surface to make it longer-lasting.